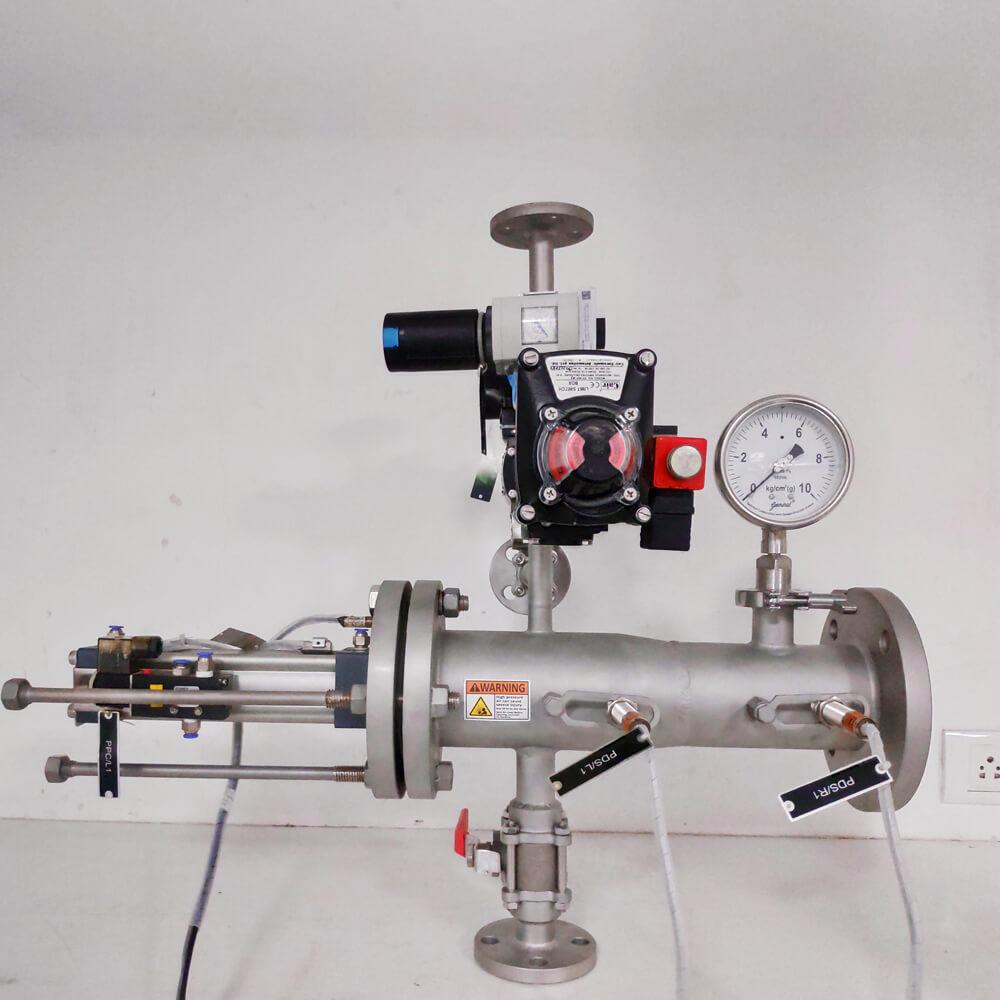

Industrial pigging systems are innovative and efficient solutions used in various industries, such as oil and gas, food processing, and chemical manufacturing. These systems are designed to clean pipelines, recover valuable product residue, reduce waste, and improve overall operational efficiency. The term “pigging” refers to the process of using a cylindrical device called a pig to clean or inspect pipelines. The pig is propelled through the pipeline by the flow of a liquid or gas, effectively removing contaminants and ensuring smooth operation.

Industrial pigging systems offer numerous benefits including increased throughput capacity, reduced downtime for maintenance, improved product quality, and enhanced safety. With advancements in technology, industrial pigging systems have become increasingly sophisticated and customizable. They can be tailored to suit specific requirements of different industries, accommodating varying pipe diameters and product types.

Benefits Of Implementing Industrial Pigging Systems

Implementing industrial pigging systems offers numerous benefits for various industries. Firstly, pigging systems improve operational efficiency by reducing downtime and maximizing productivity. The use of pigs eliminates the need for manual cleaning, resulting in faster product changeovers and reduced maintenance time. This leads to increased production capacity and decreased costs.

Secondly, pigging systems enhance product recovery by effectively removing residual products